Be Prepared for Natural Disasters Like Hurricanes, Fires, Floods, Tornados, and More

|

This article was updated on 07/16/21.

Ads we feature have been independently selected and reviewed. If you make a purchase using the links included, we may earn a commission, which helps support the site. Thank you for your support.

Ready.gov (owned by the Department of Homeland Security) says, “Disasters Don’t Wait. Make Your Plan Today.” Good point. We never thought our neighborhood would flood, but it did. While we had flood insurance, others did not and had to rely on FEMA. The city has been ignoring drainage issues for years, all the while issuing building permits willy-nilly. Concrete surfaces don’t absorb rain water. At some point, we will all experience fire, earthquake, or a hurricane. This is how Ready.gov suggests that we prepare.

Week 1: Make a Plan

Make your plan now. You and your family may not be together if a disaster happens, so it is key to understand which types of disasters could affect your area. You should all know how you’ll contact each other and reconnect if you become separated. Establish a family meeting place that’s familiar and easy to find. For example, a neighborhood park or a local school that might be serving as an emergency shelter.

Week 2: Build a Kit

Following an emergency, you might need to survive on your own for days. Being prepared means having your own stock of food, water and other supplies to last for several days. A disaster supplies kit is a collection of basic items your household may need in the event of an emergency. You don’t have to be an all-out prepper but having the essentials on hand is, well, essential.

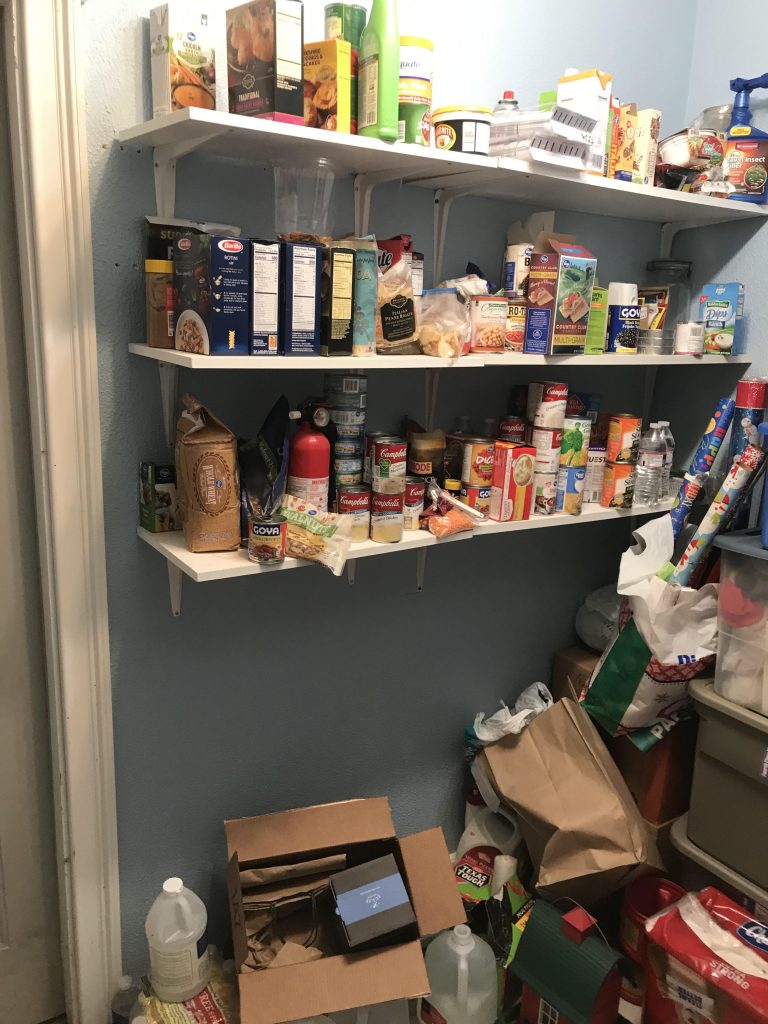

In my own home, I built a pantry off the kitchen. We keep it stocked with food, water, prescription medicine, and a camp stove. Basically, the room is our kit. And we even keep a stock of toilet paper. We all remember the empty shelves when the COVID-19 pandemic broke out!

Week 3: Prepare for Disaster

Hurricanes are dangerous and can cause major damage because of storm surge, wind damage, and flooding. Don’t wait to do things like removing old dead tree limbs and securing things that have the potential to become projectiles. It’s a good idea to have a firearm or two and a stock of ammo. Just look at what Antifa and BLM are doing in our streets and society hasn’t broken down yet! No one is going to respond to your 911 call after a certain point.

Know what disasters and/or hazards might affect your area, how to get emergency alerts (an emergency crank-operated radio), and where you would go if you and your family need to evacuate. Make sure your family has a plan and practices it often.

Don’t wait until the day before to try to find plywood, batteries, and other items.

Week 4: Teach Your Kids About Disasters

Talk to your children about being prepared for emergencies. They need to understand what to do in case you are separated. Make them feel at ease by providing information about how they can get involved. Work out scenarios and the proper responses.

National Preparedness Month is easy when it is broken down like this. The process of divide and conquer works well and gives you time to consider things you have not anticipated.

Got a blog or website? Want more revenue? Monetize it!

References and Further Information

- Ready.gov (owned by the Department of Homeland Security)

- FEMA.gov

- What is Covered by Standard Homeowners Insurance?

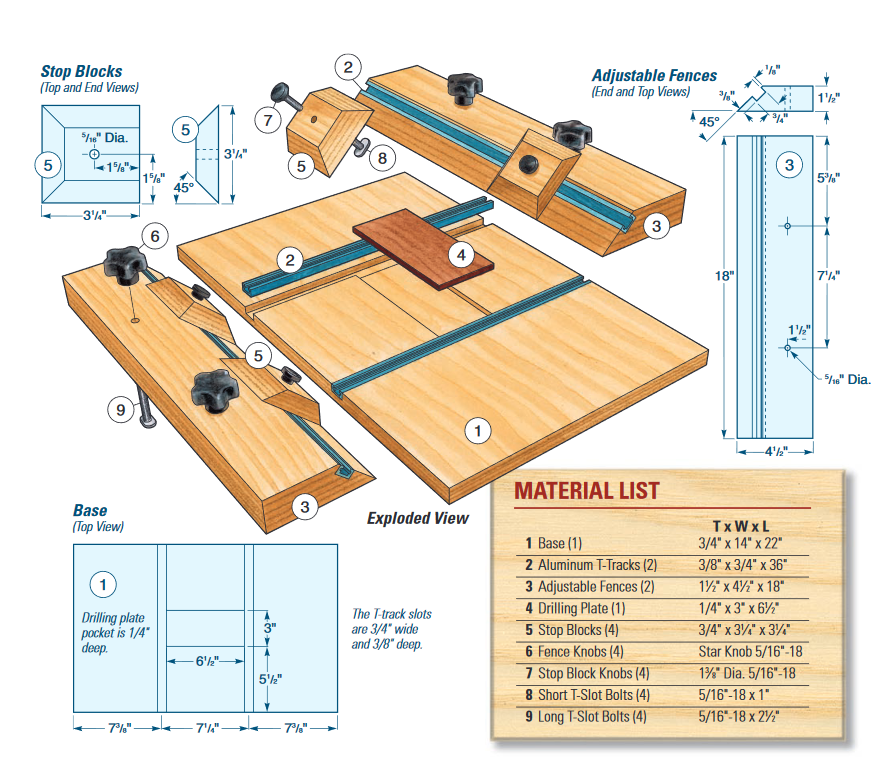

- Build a Walk-in Pantry

- The History of Antifa

- 8 Prepper Tips for Beginning Survivalists

- Hurricane Preparedness Checklist

Looking for more great content? Visit our partner sites:

I offer article and blog-writing services. Interested? Hire Me!

Did you find this article helpful? Thanks for supporting this free site with a small donation!

Visit Kelly’s profile on Pinterest.

About the Author:

Kelly R. Smith is an Air Force veteran and was a commercial carpenter for 20 years before returning to night school at the University of Houston where he earned a Bachelor’s Degree in Computer Science. After working at NASA for a few years, he went on to develop software for the transportation, financial, and energy-trading industries. He has been writing, in one capacity or another, since he could hold a pencil. As a freelance writer now, he specializes in producing articles and blog content for a variety of clients. His personal blog is at I Can Fix Up My Home Blog where he muses on many different topics.

Kelly R. Smith is an Air Force veteran and was a commercial carpenter for 20 years before returning to night school at the University of Houston where he earned a Bachelor’s Degree in Computer Science. After working at NASA for a few years, he went on to develop software for the transportation, financial, and energy-trading industries. He has been writing, in one capacity or another, since he could hold a pencil. As a freelance writer now, he specializes in producing articles and blog content for a variety of clients. His personal blog is at I Can Fix Up My Home Blog where he muses on many different topics.